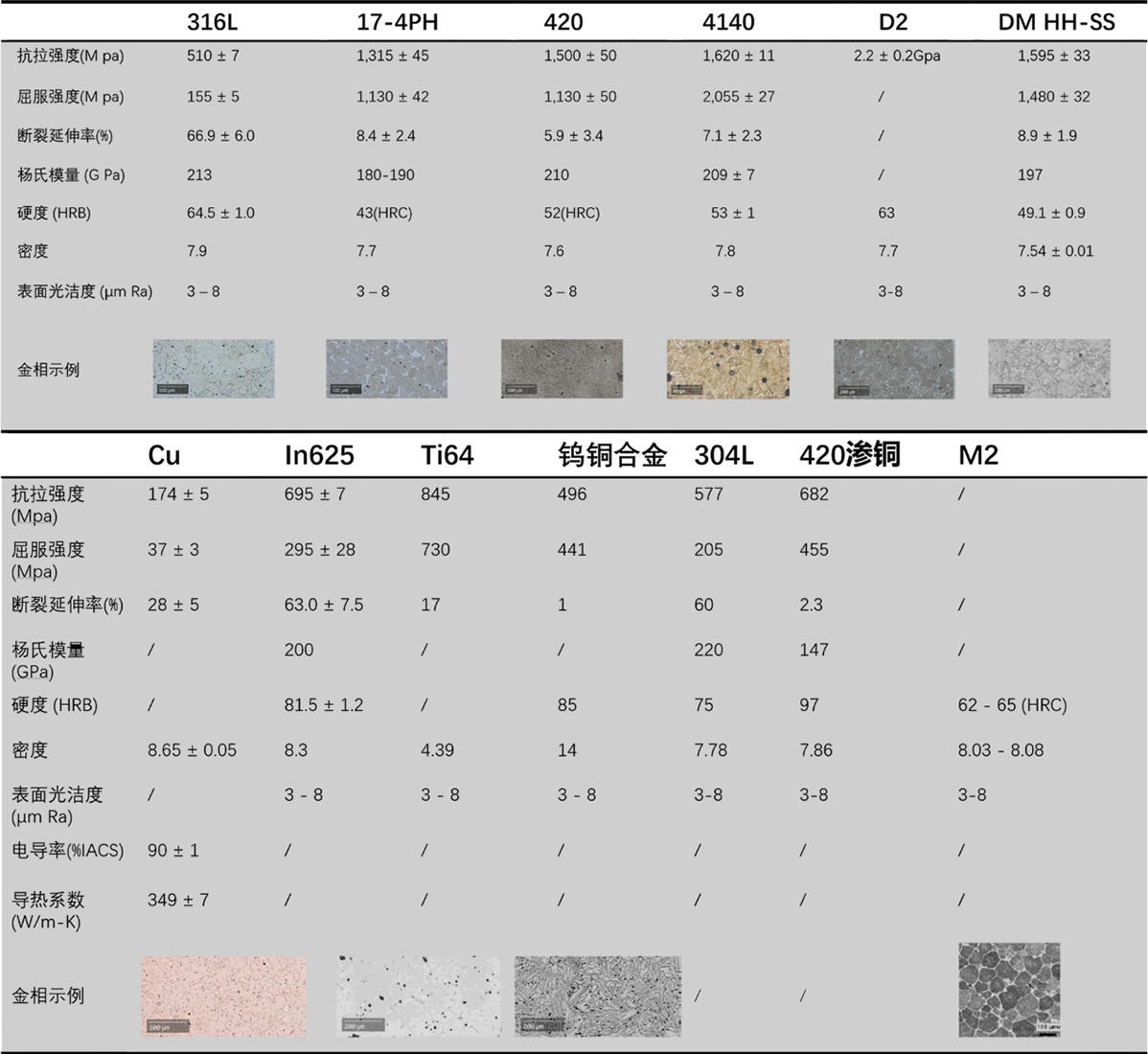

Binder jetting 3D printing technology expands the printable particle size range of powder to 0-100um due to its specific powder falling and powder laying structure, and no heat source forming, and the material types are expanded from the materials currently used in PBF to MIM, PM, casting and other forming technologies, and has many advantages in the fields of cemented carbide, high specific gravity alloys, refractory alloys, high conductivity and high reflection materials.

DEW currently provides raw material solutions for different types of binder jet 3D printing equipment, helping customers solve powder molding, sintering and post-processing from key parameters such as powder composition and powder particle size series of questions. |